SINGLE STAGE VACUUM PUMPS

110/220VAC Vacuum Pumps

Single stage vacuum pumps operate on 110 VAC or 220VAC. Picking the proper size pump from 1.five cfm to 9 cfm is dependent upon your distinct application. These pumps one engineered especially to assist you do your career faster and greater.

Substantial  efficiency-CFM rated as ?¡ãfree air displacement.?¡À150micron area rating. Heavy duty substantial torque motor-assures cold weather staring.

efficiency-CFM rated as ?¡ãfree air displacement.?¡À150micron area rating. Heavy duty substantial torque motor-assures cold weather staring.

Low working temperature-improve efficiency and vacuum.

Forced-feed lubrication design-help minimize working temperature and far better Lubrication.

DUAL STAGE VACUUM PUMPS

110/220VAC Vacuum Pumps

Dual stage vacuum pumps operators on 110 VAC or 220VAC.Superior dual-stage design pulls deep vacuum to 50 microns. Design and style of those one.five,three,5,eight,10,12 CFM pump improvements develop about the performance-proven high-quality attributes. Whatever your vacuum pump requirements, the appropriate pump will visit work with you.

Dual stage design-second stage starts pumping at a decrease pressure to pull a deeper ultimate vacuum.

Stopping oil-returning design-prevents pump oil from becoming sucked to the system if a power loss occurs.

Gasoline ballast-speeds evacuation and keeps oil cleaner. Substantial oil reservoir-lightweight and superior dilute corrosive contaminants.

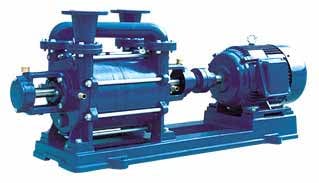

ROTARY PISTON VACUUM PUMPS

The series HGL, HG pump is actually a variety of single-stage and single-cylinder rotary piston vacuum pump. It truly is enormously improved series H rotary piston pump and includes 4 patents; its common abilities possess a fantastic improvement. Rotary piston vacuum pump is usually a type of vacuum production products ideal for pumping ordinary gases and condensable gases(when a gas ballast applied). The pump must be fitted with proper add-ons if gas is rich in oxygen, explosive, corrosive to ferrous metal, chemical reactive with vacuum pump oil. Operation principle present in working principle graph: A rotary piston with slide valve across eccentric wheel driven by shaft inside the housing. Piston pole can slide and swing freely in arch track. The whole pump chamber is divided into chamber A and chamber B by piston. When shaft rotates the volume of chamber A and chamber B are altered repetitively, to ensure pumping objective can be achieved.